Posts By Badger

New Chisel Roll

My wife just made me a new chisel roll as a prototype to test out. She’s considering making them available for sale down the road, but she wanted to make me one to see how it worked out. She even made it in this cool “wood grain” fabric that she found, which is kind of neat. Sure beats plain old canvas!

It fits quite a few chisels (my entire set of carving chisels), and has some room for more. In practice I think we’re considering removing some of the space between the two sides, to make it a little safer to get chisels out, but I’d be happy to throw this in my toolbox and take it somewhere like Port Townsend for a woodworking class or something.

The chisels are secure when rolled up because the blades pinch together in the middle when tied up, and makes it very unlikely for them to slip out. Plus putting them in handle first helps you know what chisel to grab, prevents the very sharp blades from tearing up the bottom of the pocket.

She was curious if anyone would be interested in these (with different fabric probably, but she has enough to make at least one more). So if you’re interested, please send me a note and we can chat.

Badger

Tuning up a Dado Plane

A while back I picked up a set of three Dado planes, one of which was 3/4″ in good shape from the ever amazing tool seller Hyperkitten. Of course that’s the really useful size in our modern day lumber world. I hadn’t spent the time to tune it up to working condition, so this afternoon was a good time. I needed to make some grooves in the case for the drawer supports. I could easily do it with my carcase saw and some chisel work but I’ve been wanting to try this plane out.

I started out taking it apart to check the steel of the blades, and nickers which turned out to be in rather good shape. I wire brushed it a little to clear some bulk of the crud off, and they both looked quite decent although the long part of the nicker had a bend in it. The plane body was solid, no checks or warping.

I started out on a Medium India stone on the blade, and worked through to Translucent and finally stopping all by hand. I was a bit worried that the nickers would be problematic, but after propping my stones up on the case I was able to get to the inside edge (never the outside edge if you can avoid it, you don’t want to make the over all width go down.)  As I worked the inside slowly I was having problems keeping it steady, and on closer inspection the last guy to sharpen it had the same problem. It was rounded a bit, but the points where sharp so I figured it would be good enough which turned out to be correct. I tweaked the slight bend in the top part of the nicker, and re-assembled it.

I tested it out on a scrap piece of pine, and it worked fantastic. I used a fence clamped to the board as a guide, and set the depth stop by eye. The sides of the trough were square, and the bottom was smooth enough. It took very little effort to use, and is now my new favorite way to make dados! I put it right to use on the sides of my dovetailed three drawer carcase project. The prototype is in Pine, and check out the cross grain shavings I was getting with the dado.

All in all, I’m VERY pleased with this plane. Thanks Josh! (If you’re in the market for old user tools, follow his blog for excellent deals. He has never steered me wrong, and he finds great tools. Highly recommended.)

Badger

Old German Workbench

My wife and were out Antique store browsing, and I ran across this interesting piece of work.

It’s supposedly from the 1800’s, and was German in origin. The plate for the shoulder vise was missing, but otherwise it was complete. It was very well worn, and had seen a lot of use in it’s day. I couldn’t afford it, or had any space for it, but it was pretty cool to check out.

Stuff like this is pretty rare out here on the West Coast. I’m sure those East Coast people are all like “whatever dude, I see five of those every time I turn around”. Heh.

Badger

Drawing some Gothic Tracery for carving layout

I’ve always been fascinated with the carving examples of “Gothic Tracery”, and the intricate and delicate feel to them. After taking the “By hand and by eye” class with Jim Tolpin, and the ideas I picked up behind laying out things with a compass, I was somewhat inspired to do a little research. However, there is VERY little out there for the aspiring carver to pick up and learn from.

I did finally find a book on Google Books that was of some help: Practical wood-carving: a book for the student, carver, teacher, designer, and architect by Eleanor Rowe. She touches on Gothic Tracery in some what obscure language in the book, and I sat down today to try and figure out how to lay this stuff out.

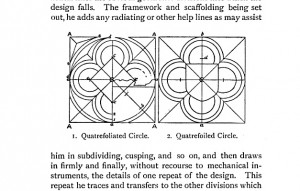

Starting with this (Page 99)

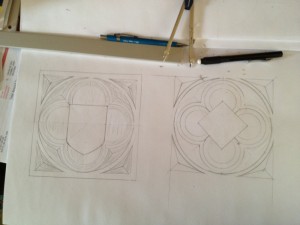

I came up with this:

I learned a few things, and actually feel pretty good about laying out this basic “quatrefoil”. No measuring happened, just arcs and lines. It’s a starting point, and I’m going to try and get some time down in the garage to lay this out, and try some carving.

This one was my favorite of the two, where I used a midpoint on the radius to base the circular lobes on. I know that makes no sense, but putting compass to paper really helped figure this stuff out in my head. The layout was fairly simple once I got started, it’s just complex looking to start out doing.

Let’s see what happens when the chisel hits the wood.

Badger

Bit of Pen Work…

Finished up a special order for a set of 10 pens to be used as a graduation gift at a ceremony.

This is for a repeat customer of mine, and I’m pretty pleased with these pens. The Koa wood I used showed a lot of variation, and has some very nice grain patterning, as well as a substantial curl in some of the wood.  The Paduak looks gorgeous as always, and there was on in Rosewood by special request.

I haven’t had a lot of work in the Pen department for a while, so it was good to get down to the shop and turn a bit of wood again.

I did have one blow up slightly at the last possible moment, so I had to make one extra in the 11th hour. The wood near the tip pulled up slightly, and was noticeable. It’s not terrible, just not up to my quality standards. Sucks that it happened at the last possible second, when I would have to totally pull the thing apart (no easy task, and no guarantee of success either).

Badger

Starting a new project for some drawers in pine.

Starting a new project in the shop after some downtime. I wanted to work on a couple skills, and try out a few new ones, so I grabbed a left over pine board (with knots, and voids, and all) and set out to make set of small drawers for my wifes sewing room.

Last night I fit the last two corners of dovetails, and it went together pretty well. This is a minor miracle for me really, as I’ve had a hand of these simple dovetail project go awry at this point, so I was very happy to see this come together. I used a much improved marking system to make absolutely sure I had lined it all up right this time, and not repeat the mistakes where I cut the pins on the wrong side, or similar rookie mistakes.

Some of the things that worked well this time:

- Using my new marking knife from Blue Spruce.

- Cutting to the line.

- Simple layout of tails with a divider to step it out, and the Lie Nielson dovetail marker.

- Sharpening and stropping my chisels before I set to work.

- Cutting the waste out with my bow/turning saw right to the line.

All in all I was pretty happy with things, except for the two times I cut my self on my chisels. I did this over two different evenings, and in true “Underhill” style managed to nick my fingers both times with the super sharp chisel.

Next steps are going to push me into new areas. I’m going to make this a three drawer chest (with a little luck, and hopefully some small amount of skill). I’m going to cut some dados and build out some drawer supports. If all goes well, then I’ll start building some drawers for it, and maybe even carve the fronts with some strapwork designs I’ve discovered.

Badger

Shop Made Turning Bow Saw

A while back I was torn between splurging on a Gramercy Turning saw, or a simple (but quality) coping saw. In the end I compromised, by getting the Olson Coping Saw (no regrets there, great tool) and buying the parts for the Gramercy Turning Saw. Last night I was in a mood, and needed to break out of a funk so I went down with the intention of cleaning the shop, or maybe marking out a box using whole number ratios.

Instead I made a turning saw from the kit.

It went surprisingly quickly, and I was able to put it together in about two hours all told. I used some straight grained oak 1×2 I had picked up at a Home Center, and cut it down to size. Rather than try to rip the length down on such a small piece, I just put it in the vise and planed off the excess to my line with a Jack plane. I used another small bow saw I had picked up at a salvage place (with a terrible blade, so I never use it) as a pattern and went to it.

I cut the arms to length, and traced the outline of the existing bow saw onto the wood. I cut out the head shape, and the curve with my coping saw and chisels. I then used my spokeshaves from Lee Valley to smooth out the rough spots and a some rasps to smooth the head a bit. I need better rasps I have decided, but that’s for later. I drilled the hole in each arm with a eggbeater drill, and while they were a bit off center I don’t think it will matter much in practice.

Inserting the pins into the arms, and slotting the blade in, I measured the distance between the arms, and used that for the cross bar length (adding a little for the small tenons).

This was my first time cutting a mortise and tenon in a really long time, so I took it slow but it thankfully went together pretty quickly. I used a 1/4″ Narex mortise chisel to carve the trench (after a quick honing) and after a little fumbling I got the movements down pretty quickly. Then I cut a small tenon on each end of the cross bar to fit each side, and cut the corners of the tenon to allow it to move a little side to side as the frame is tightened and loosened. If it was left square it could cause issues as it tightened.

Once this was all fitted together, I grabbed a scrap piece of Wenge and some string that I will replace later with some tough twine, and tightened it up. I was able to get good tension, and it held together really well. I took it back apart, and shaped the hand hold area with the spoke shaves and made sure all of the edges were rounded.

Next step will be to glue up some blocks onto the brass pins, and turn a couple of nice knobs. Right now my lathe is buried under the wood for my new work bench, but it will work like this for now if I need to do any fret sawing .

All in all I’m pleased with this project, and how quickly it came together. I would highly recommend the kit to anyone who needs it. As always Gramercy Tools are top quality.

Badger

Check out Blue Spruce

I went to the Lie Nielson Hand Tool event today to check out their latest offerings, and bask in the glow of expensive but totally worth it tools. They had a couple of other guest exhibitors including Blue Spruce Toolworks out of Oregon. I’ve admired his work from afar (i.e. the internet) but to see the tools up close and personal is hard to describe. All of his work is absolutely top notch, functionally as well as aesthetically. His chisels area amazing, his marking knives sublime. And to top it all off, Dave is a really nice guy who knows his craft.

I picked out a nice Cocobolo marking knife for myself, for my upcoming birthday. It was a bit of splurge, but it’s a really nice tool. It will make the marking of dovetail pins a lot easier for sure, plus it’s quite a nice looking tool as well.

I heartily recommend checking out his wares.

Badger

Sharpening up some carving chisels

I needed a break from a four year old who was testing his limits a little, and went down to the shop to sharpen some chisels. Now, I know that SOUNDS like a bad idea, and it probably was.

I’ve been wanting to modify the profile of these old chisels I picked up a while back to be more like the flat carving chisels I have in use already. I picked them up in the early phase of my tool acquisition period, which means I bought a bunch of stuff whenever I found it not always buying something I might need or want. These were picked up in a bundle, hoping to be paring chisels but look a bit more like carving chisels because of the way the tang enters the handle.

Regardless, I have good chisels now, and these needed to find a new life. They worked OK with a single bevel when I needed to outline a carved design or something, but I thought they could use a good sharpening and the one small flat carving chisel I have was a double bevel.

First I set the angle by eye on the tool rest on my grinder, and added the bevel roughly to what I wanted with a slow speed white wheel I use for sharpening my turning tools.

Then I pulled out the oil stones and put them through the grits free hand.

I started with the Coarse India from Norton, and worked the roughness off the grinder and adjusted the bevel slightly.

Next I used the Medium to refine the edge a little.

A few swipes on the Translucent Arkansas and I was nearly done.

Final step was a few strokes on some leather charged with “green stuff” for a final mirror polish.

I make it sound simple, but this sharpening regimen took me years to figure out, and purchase. I’m really happy with what I can do in a fairly short amount of time with these stones, and I don’t have to bother with water stones. I know most everyone else loves them to death, but I find the mess abhorrent personally. Everyone should find a system they like and stick with it, that’s what I’ve heard and that’s what I also recommend.

In the end I was able to slice paper with these edges, and the cut wood very nicely when used in a “stab cut” to set in an outline. All in all I’m happy. (And I was able to burn off the mood the willful child had caused, without cutting myself. Working in my shop relaxes me so, I need to do it more.)

— Badger

Question about how to start carving…

In response to my post tonight about my carved tool tote, I got a question about how to start carving similar stuff. The answer I thought might be of more general interest, so I thought I’d post my answer here.

“I was reading your blog post about carving your tool tote. I would like to get started doing some really small and simple carvings. Do you have a book/dvd that you recommend and what are a few needed tools to get started?”

The answer kind of depends on what kind of carving you want to do really, but since the question was about the stuff I have been doing I’ll answer in that regard.

DVD

- Peter Follansbee – 17th Century New England Carving

- Peter Follansbee – 17th Century New England Carving: Carving the S-Scroll

http://www.lie-nielsen.com/catalog.php?grp=1320

Scroll down a bit for the first one, it’s the best for starting out. Then follow up with the S-Scroll dvd. Absolutely top notch stuff, and very easy to understand and learn from.

Blog

Reading Peter’s blog: http://pfollansbee.wordpress.com/ from start to finish. :) That is if you are a geek about history and woodworking like me. Otherwise search on carving.

Books

Tools

I posted a while back about my starter set of tools, based on the recommendations of Peter Follansbee and his basic kit.

https://badgerwoodworks.com/2010/12/peters-carving-tools-interpreted/

this has the list of Tools I started with and how I got the list.

- Pfeil Gouge #9/10 mm

- Pfeil Gouge #6/20 mm

- Pfeil Gouge #8/13 mm

- Pfeil Gouge #8/20 mm

- Pfeil Gouge #5/12 mm

- Pfeil V-Parting Tool #12 8mm

I did about 4-5 fully carved pieces with that set before I started expanding. I’ve added about half dozen chisels so far, but only as I need them for specific projects. The set above is a decent starting place I figure for the kind of carving I do. It’s hard to say specifically what you’ll need since you might have a different design style in mind, but a good V tool and small variety of gouges will be a good as place as any to start.

Here is part of my current kit, which I used nearly off of these for the Tool Tote carving.

Hope that helps.

Badger